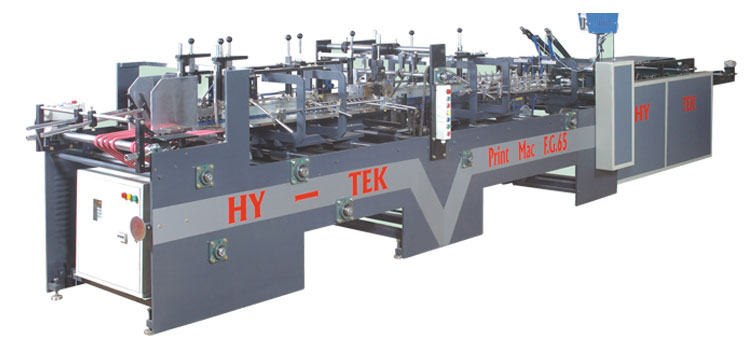

CARTON FOLDING & GLUING MACHINE

Hi Speed Folder / Gluer for Pasting Duplex Board

Salient Features :

FEEDER UNIT :Pile of Carton blanks is placed in the feeder between two adjustable side plates. Feeder belts pull the. bottom blank from the pile into the machine. Feeder equipped with Electro magnetic clutch for instantaneous starting and braking.

PREFOLDER :Crease lines 1 & 3 are prefolded in this section and laid flat again & transfered to folding section. Various attachments for lock-bottom, CD covers etc can be integrated here.

PRESSURISED TOP TRACK SYSTEM :Spring loaded Pin mounted with bearings to apply pressure.

FOLDING STATION :Sequential gluing is applied and seams are joined. The cartons are transfered to compression and delivery section. Batch counter and kicker track output.

COMPRESSION / DELIVERY SECTION :This unit runs relatively slowly. Here the cartons move between two rotating compression aprons, to allow the glue to bond the cartons under controlled pressure.

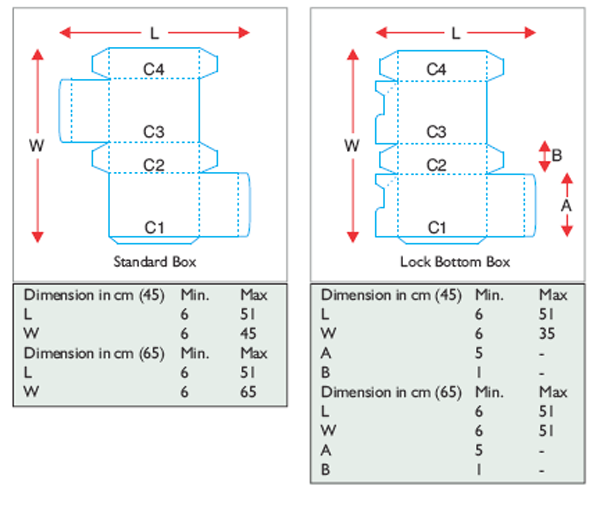

MIN. OPEN BLANK :12 cm (l) x 10 cm (w)

OPTIONAL UPGRADES :

- A pre-feeder can be installed ahead of the feeder for an uninterrupted flow of blanks into the machine.

- 3 Gun nozzle slot die coating system can be offered on request.

| MODEL | HY-TEK FG-45 |

| Substrate | Duplex Board |

| Size Width (Open blank) Maximum | 45 cm |

| Minimum (Open blank) For Lock Bottom | 12 (L) X 10 cm (W) |

| Drive:AC Motor VFD | 5 HP (3.7 kW) |

| Speed Side pasting, Lock Bottom | 30 / 40,000 cartons p/h, 15 / 18,000 cartons p/h |

| Footprint: Length X width | 7.95 X 1.15 mtrs. (26 X 4 ft): |

| HY-TEK FG-65 | HY-TEK FG-80 |

| Duplex Board | Duplex Board |

| 65 cm | 80 cm |

| 12 (L) X 10 cm (W) | 12 (L) X 12 cm (W) |

| 7.5 HP (5.6 kW) | 7.5 HP (5.6 kW) |

| 30 / 40,000 cartons p/h/ 15 / 18,000 cartons p/h | 30 / 40,000 cartons p/h, 15 / 18,000 cartons p/h |

| 7.95 X 1.2 mtrs. (26 X 4.3 ft): | 7.95 X 1.2 mtrs. (26 X 4.3 ft): |